Dimensional Data Analysis & DOE

Plazology are experienced users of Minitab, an effective statistical software, which provides conclusive and accurate dimensional data, process and trends. Plazology are Green & Black Belt certified via Missouri State University and Gemba Academy.

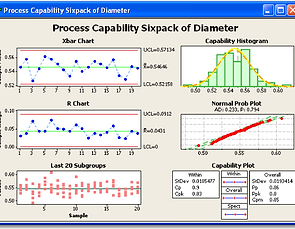

A typical injection moulding part drawing will have a number of First Article & Control Dimensions which need to achieve CPK/PPK values >1.33 (CPK/PPK refer to short & long term capabilities of a process). This can create hundreds of data points across a multi-cavity mould which require presenting in an easy to understand and professional manner. Using Plazology’s systematic approach to sample collection, areas of concern (be it part/process or mould) can be rapidly identified and assessed.

Dimension reports generated by Plazology are graphically presented in a way that allow customers to investigate any non-conformities, giving deeper insight within a short time frame. The graphs show patterns in the data which would not necessarily be highlighted in a standard dimensional report. With the in-depth reports, customers can quickly compare different master-batches and polymers against each other, to see which gives better dimensional stability and performance.

Plazology also offers Dimensional DOE, a great tool if used correctly, to understand which key parameters are driving dimensional variation in components (this can also be used to reduce quality defects). Plazology support the creation of true SPC for ongoing production monitoring. Plazology’s in-depth knowledge of moulding process set-up with process tolerance control reduces the need for ongoing inline inspection.

Key areas Plazology can support customers with:

-

Drawing Tolerance Control

-

Measurement Fixture Procurement and Management

-

Measurement System Analysis (MSA- Gage RR)

-

Injection Moulding SPC

-

Dimensional Correlations

-

Minitab Data Analysis

-

Monte Carlo Simulation

-

Dimension DOE

-

Measurement methods (CMM, CT Scanning, Vision)

-

3D Scanning & Reverse Engineering

LET OUR EXPERIENCE & EXPERTISE TAKE THE DOUBT OUT OF YOUR NEXT PROJECT!

Our team at Plazology can provide a totally unbiased “fresh set of eyes” to check out all those variables which can so often be contributing to a problem in the task of producing a new injection moulded product.

Plazology launch new simulation product development service for the plastics industry VDMA®